People shopping for new ATV- or UTV wheels often find themselves overwhelmed by all the different specs and numbers. Terms like wheel offset, backspacing, ET number, and positive or negative offset confuse people the most.

While these terms seem complicated, they are critical for proper wheel fitment. In this article, you’ll learn their meaning and how to choose the appropriate offset for your ATV.

What Is Offset on ATV and UTV Wheels?

Wheel offset is a measurement used to determine how far in or out a wheel sits relative to the vehicle’s wheel hub and axle.

Offset is the distance between the hub mounting surface and the wheel’s true centerline and can be positive, neutral, or negative. For most vehicle types, an ET value measured in millimeters (mm) quantifies the offset.

However, the Powersports industry has adopted a different offset format.

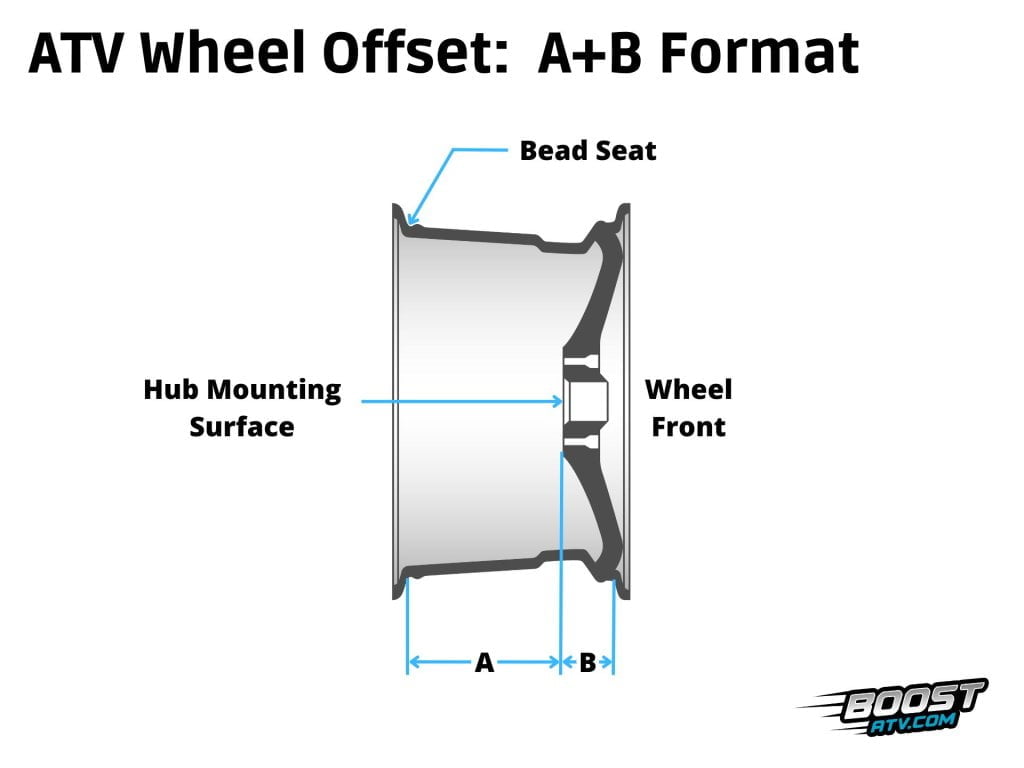

On ATV and UTV wheels, the offset is advertised in an A+B format (in inches), where A is the distance from the mounting surface to the rim’s inner bead seat, and B is the distance from the mounting surface to the outer bead seat. The sum of the two numbers equals the rim width.

Some manufacturers have added the acronym “PS” before the two numbers, which stands for PowerSport.

Occasionally, you’ll come across people who say the first number equals the wheel’s backspacing, which is inaccurate. We’ll look at what backspacing is later in the post.

The offset is one of several measurements of a wheel’s fitment specifications.

Key metrics, such as wheel dimensions, bolt pattern, and lug nut sizes, are just as crucial for a proper fit. Click the links to learn more.

Confused? Don’t worry; all of this will make sense in a minute.

How Does ATV Wheel Offset Work?

As we’ve mentioned, wheel offset is measured in one of two ways: ET number (millimeters) or an A+B format (inches).

Offset measured by an ET number is well established as the automotive industry standard, while the Powersports industry typically uses the A+B format.

Many ATV and UTV wheel manufacturers use both metrics to accommodate those from an automotive background and are more used to using the ET number.

Below, you’ll learn how both metrics work and how they differ.

ET Offset Explained

The abbreviation ET has a German origin and stands for “Einpress Tiefe,” which loosely translates to insertion depth.

The ET number is a millimeter (mm) measurement of how far the hub mounting surface is from the wheel’s geometric centerline (the symmetry axle).

In other words, it indicates how far in or out the wheel sits relative to its centerline.

- As the ET number increases, the wheel position shifts further under the fender, resulting in a narrower vehicle stance.

- Conversely, as the ET number decreases, the wheel extends outward, creating a wider stance for the vehicle.

The fact that a higher ET number moves the wheel further in while a lower number moves it further out is what confuses many at first. It may take some time to get one’s head around this concept.

The ET number (when provided) is cast into the backside of the wheel.

For example, an offset of ET25 indicates that the mounting surface sits 25mm outside the wheel’s centerline. This is known as positive offset.

On wheels with an ET number of ET-25, the mounting surface sits 25mm inside the wheel’s centerline. This is known as negative offset.

ATV/UTV Offset Explained (A+B Format)

In most ATV and UTV tire listings, you’ll notice that the wheel offset is provided in an A+B format rather than an ET number.

Wheel offset in the A+B format is based on the mounting surface position relative to the bead seats.

- The first letter (A) represents the distance from the hub mounting surface to the outer edge of the inner bead seat, where the bead seat meets the inner flange.

- The second letter (B) represents the lip of the wheel and indicates the distance from the hub mounting surface to the outer edge of the outer bead seat where the bead seat meets the outer flange.

The sum of A+B equals the width of the rim, which measures from the inner bead seat to the outer bead seat. The bead seat is where the tire beads press against the wheel flanges.

Let’s examine a 14X7, 4+3 wheel, a typical ATV wheel size and offset.

- The first number is 4, indicating that the hub mounting surface sits four inches outside the inner bead seat.

- The second number is 3, indicating that the hub mounting sits three inches inside the outer bead seat.

- The wheel is 7 inches wide, 4+3=7.

Another way of widening the stance of your ATV is by installing wheel spacers.

Understanding Negative, Neutral, and Positive Wheel Offset

Positive and negative offset are terms used to quickly determine if the wheel’s geometric centerline sits inside or outside the hub mounting surface.

- On wheels with a positive offset, the mounting surface sits outside the wheel’s centerline.

- On wheels with neutral or zero offsets, the mounting surface sits parallel or in line with the wheel’s centerline.

- On wheels with a negative offset, the mounting surface sits inside the wheel’s centerline.

- If the ET number has a positive value, the offset is positive. If it has a negative value, the offset is negative.

- The wheel has a positive offset on A+B format offset listings where the first number is bigger than the latter. If both numbers are equal, the offset is neutral. And if the first number is smaller than the latter, the offset is negative.

The terms negative, neutral, or positive offset apply for both offset formats, but with one significant difference.

From the ET number, you can determine not only if the offset is negative or positive and how much the offset is.

- A wheel with an offset number of ET25 has a positive offset, and the mounting surface is 25mm outside the wheel’s centerline.

- A wheel with ET0 has neutral or zero offsets.

- A wheel with an offset number of ET-25 has a negative offset, and the mounting surface is 25mm inside the wheel’s centerline.

On ATV and UTV offset, however, you need to calculate how much the offset is

- A wheel with an offset advertised as 4+3 has a positive offset of about 1/2 inch (4-3/2).

- A wheel with an offset advertised as 3.5 + 3.5 has neutral or zero offset.

- A wheel with an offset advertised as 3+4 has a negative offset of about ½ inch (3-4/2)

What Is Backspacing on ATV and UTV Wheels?

The backspacing on ATV and UTV wheels is the distance from the hub mounting surface to the inner face of the wheel (its utmost inner edge). A wheel’s backspacing measurement is used to determine how far into the wheel well the wheel protrudes and to identify any clearance issues.

It’s a common misconception that the first number in an ATV or UTV wheel’s offset is equivalent to the wheel’s backspacing, but this is typically inaccurate by about ½ inch. Let me clarify the reason for this.

The offset numbers, when combined, are always the same as the wheel’s width. Both measurements are measured from the bead seats, not the outside of the rim.

However, as backspacing is a measurement used to determine how far the wheel protrudes inwards, it doesn’t stop at the bead seat; it goes to the back face of the wheel. On most wheels, this equals about ½ inch.

Generally, the backspacing on ATV and UTV wheels is ½ inch higher than the first number in the offset measurement.

Using a formula, you can convert from offset to backspacing and vice versa.

How to Convert Offset to Backspacing

(Wheel width (in) + 1)/2 + Offset (mm) / 25.4 = Backspacing (in).

For example, with a 7-inch wheel with a positive offset of ET25, you get this calculation:

- (7+1)/2 + 25/25.4 = 4.98 which equals a backspacing of five inches.

The formula also works with negative offset wheels. Let’s use a 7-inch wheel with a negative offset of ET-25 as an example:

- (7+1)/2 + (-25)/25.4 = 3.02, which equals a backspacing of three inches.

How to Convert Backspacing to Offset

When calculating the offset based on the backspacing, you will not get an accurate ET number because wheel backspacing is already rounded to the nearest inch. So, it’s best to take the result with a pinch of salt and ask the manufacturer for the exact ET number.

Backspacing (in) – (Wheel width (in) + 1)/2 x 25.4 = Wheel offset (mm).

Then, round the answer to the nearest millimeter to get the ET number.

For example, with a 7-inch wheel with a listed backspacing of 3, you get this calculation:

3-(7+1)2*25.4 = -25.4, rounded to a calculated offset of ET-25.

Why Is Wheel Offset and Backspacing Important?

Wheel offset and backspacing are essential metrics to ensure the wheel doesn’t sit too far out or into the wheel well relative to the mounting surface.

People typically need wheels with a more negative offset when installing bigger tires or changing to a wider rim with more backspace.

If the offset is too high (positive offset), the wheel backspacing number may exceed the available backspace inside the wheel arch. This can cause issues such as:

- Tire rubbing against suspension components, brake lines, or the inner wheel well. This could severely damage any parts involved. Rubbing is more likely when riding over bumps or during hard cornering.

- Reduced turning radius due to rubbing, preventing the wheel’s full range of motion.

- Increased risk of tipping due to more narrow track width.

If the offset is too low (negative offset), the wheel sits too far out, which may lead to a different set of issues, such as:

- Tracking issues. If your ATV has a wider track width than most, it can be a real pain to ride trails where the ruts are made from more narrow vehicles.

- Increased wear. As the wheel moves outwards, the load on wheel bearings and suspension bushings increases significantly, leading to faster wear and premature failure.

- Splashing. You don’t realize how vital the fender flares are before you’ve ridden an ATV with wheels that protrude a couple of inches outside the edge of the protective flare.

- Less responsive handling and more rigid steering. As the wheels move out from the wheel hub rotation point, they become increasingly more challenging to turn. This makes for less responsive handling and increases strain and wear on the power steering system.

The ET Number Is More Accurate Than ATV/UTV Offset

Often, you’ll find that the ET number on the back of the wheel doesn’t translate directly to the advertised A+B format offset.

That is because ATV and UTV offset in inches is typically round to the nearest inch out of convenience and to ensure A+B stays equal to the tire width.

You can test how big of a difference there is by converting from mm offset to offset in inches:

(Wheel width(in))/2 + Offset (mm) /25.4 = first offset number in the A+B formula.

If you are working with small margins, it is advised to use the ET number over the advertised offset in inches for more precise fitment.

How to Measure a Wheels Offset and Backspacing

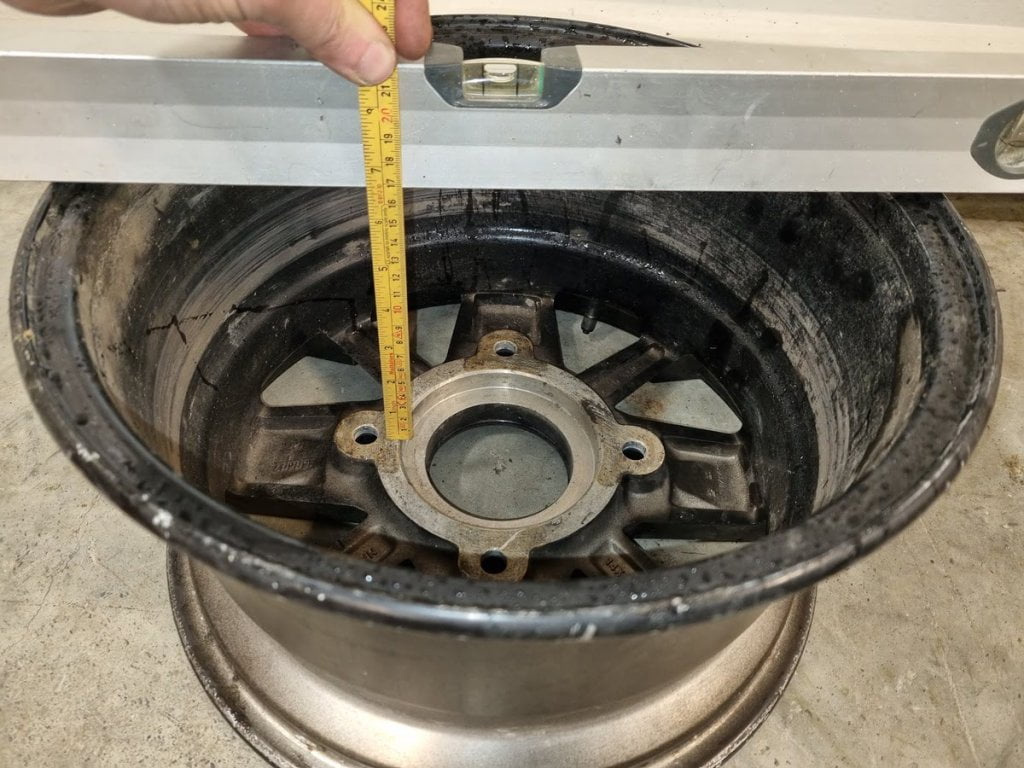

Measuring the backspacing of a wheel is relatively straightforward:

- Lay the wheel face down, with the mounting surface facing up.

- Place a straight edge across the back of the wheel, such as a level or a straight piece of metal.

- Measure the distance from the mounting surface and up to the straight edge. This is the wheel backspacing.

You usually don’t need to measure, as the ET number is stamped from the factory. But occasionally, you run into a wheel without the cast mark.

- Measure the wheel’s overall width.

- Calculate the centerline distance from the wheel edge by dividing the width by two.

- Measure the backspacing as described above.

- Withdraw the centerline distance from the backspacing distance to get the offset. (backspacing – centerline = offset)

- The offset is positive if the backspacing value exceeds the centerline value.

- The offset is negative if the backspacing distance is lower than the centerline distance.

How Does Changing Offset Affect Vehicle Overall Width?

The same-width wheel as stock but with a lower offset will make the vehicle’s overall width wider according to the difference in offset.

But if you change to wheels with a different width, the ET number alone cannot determine how far in or out the wheel sits; you also have to consider wheel and tire width.

A wider wheel will protrude farther out than one that is more narrow, even if they have the same ET value.

The added width of a wider wheel gets distributed equally by half on each side of the wheel.

An ET25 8-inch tire protrudes one inch more on the outside and one inch more on the inside than one 6 inches wide.

If you want to use a wider tire without increasing the vehicle’s overall width, you’ll need to decrease the offset by half of the added width.

For instance, if replacing a 6-inch ET25 with a 7-inch wheel, you must use a 7-inch ET12 (ET25 – 1 inch/2).

How to Know What Wheel Offset Your ATV Needs

Here are a few guidelines when choosing the offset on your new ATV wheels.

- If you’re replacing the stock wheels with same-width wheels and don’t want any changes in the vehicle’s overall width, you should use the same offset as the stock wheels. Look for the ET number on the back of the wheel, measure manually, check in the owner’s manual, or ask a dealer to learn the stock wheel offset.

- If you install a lift kit, you will likely need a lower offset wheel.

- You will likely need a lower offset wheel if you install tires more than 1-2 inches bigger than the stock size.

- Straight rear axle ATVs typically need wheels with positive offsets on the front wheels and negative offsets on the rear.

- Independent suspension ATVs typically have positive offset front and back.

- ATVs with same-width wheels front and back typically have the same positive offset.

- ATVs with a wider wheel at the back and a narrow one at the front typically use two different positive offset wheels because of the added width of the rear wheel.

- Measure backspace clearance. Generally, you should always have at least one inch of clearance between the tire and any surface.

Place a straight edge across the wheel hub and measure how much backspace you have available before you run into rubbing issues. The front wheels are the hardest to get an accurate reading as you don’t only have to consider how the suspension moves up and down but also how the wheel turns from side to side.

- Ask a tire shop for assistance. Tire shops work to find the optimal offset on their customer’s vehicles. When in doubt, asking a professional for guidance is a good idea.

- Test fit. Some test-fitting is often required, particularly for more extensive modifications where you’re pushing the limits.