Wheel bolts, lug nuts, and wheel studs all have the same function: securely fastening the wheel to the ATV’s wheel hub. However, it’s crucial to use the appropriate type, shape, and size of fastener for a safe and correct fit.

This article provides the information you need to choose the suitable fastener for your ATV.

Wheel Fastener Terminology – Different Types Explained

There are two main designs for securing an ATV wheel to the wheel hub, where the latter is most common.

Wheel bolt + threaded wheel hub: A wheel bolt goes through a bolt hole in the rim and screws into a threaded hole in the wheel hub.

Wheel studs + lug nuts: The rim goes onto studs attached to the wheel hub and is secured by lug nuts.

Across the two methods, there are three main types of ATV wheel fastener hardware:

- Wheel bolt – also known as a lug bolt.

- Wheel nut – also known as a lug nut.

- Wheel stud – sometimes (imprecisely) referred to as wheel bolt.

What is an ATV Wheel Bolt or Lug Bolt?

A wheel bolt or lug bolt is an externally threaded metal rod fastener with a flat, rounded, or conical head used to secure the wheel onto the wheel hub. The bolts go through holes in the wheel and screw into tapped holes in the wheel hub.

Wheel bolts were originally a European design and are uncommon in modern ATVs.

What Is an ATV Wheel Nut or Lug Nut?

A lug nut or wheel nut is an internally threaded fastener with one flat, conical, or tapered end and is used to secure a wheel onto ATVs and other vehicles. Once the wheel is in place, the lug nuts screw onto externally threaded wheel studs protruding from the wheel hub.

Lug nuts come in many shapes and sizes depending on stud size and the wheel’s seat design.

In modern ATVs, lug nuts and wheel studs are the most commonly used wheel fasteners.

What Is an ATV Wheel Stud?

A wheel stud is a threaded fastener that holds the wheel onto the ATV. The inner end is semi-permanently mounted to the wheel hub, and the outer end is threaded so the wheel can be secured with lug nuts. When the wheel is removed from the vehicle, the wheel stud remains in the wheel hub.

Wheel studs come in two types.

Screw-in design: This type of wheel stud has external threads at both ends. The inner end has reverse threads that screw into the wheel hub from the outside. The outer end has normal external threads for the lug nut. This type is not very common in ATVs.

Press-fit design: This type of wheel stud has external threads at one end and a splined part at the other. It is also called a spline screw.

The threaded part of the stud is inserted through a non-threaded hole in the wheel hub from the backside. The inner end of the stud has a larger diameter head with splines known as the knurl that is press-fitted into the non-threaded hole in the wheel hub.

The splines are there to prevent the stud from rotating. The protruding outer end has normal external threads for the lug nut. This type of wheel stud is used in most modern ATVs.

Some stores refer to wheel studs as wheel bolts, which could confuse buyers.

While press-fit studs are technically a kind of bolt, they do not have a head designed to be tightened by a tool. It does not turn but remains passive similar to a tapped hole that a wheel bolt screws into.

Lug bolts and lug nuts have one thing in common: they are designed to “pull” the wheel onto the wheel hub as they are tightened (lug means pull).

Related: ATV Wheel Bolt Pattern and Lug Pattern Explained

How to Measure ATV Wheel Bolts, Lug Nuts, and Wheel Studs

You must replace a wheel fastener immediately if you break or lose it. Before ordering new parts, you must ensure your chosen parts will fit your ATV.

Metric bolts are measured in millimeters, while imperial (non-metric bolts are measured in inches.

Note that different manufacturers may use slightly different measuring procedures. For best accuracy, measure with calipers and not a tape measure.

ATV Wheel Bolt Sizes Explained

Overall length: The bolt’s length is measured from the top of the head to the end of the treads.

Thread length: The bolt’s thread length is measured below the tapered part of the bolt head and to the very end of the threaded part of the bolt. In other words, the length of the bolt threads.

Thread diameter: The thread diameter or thread size is the bolt’s diameter measured on the threaded part.

Overall Width: The width or outside diameter is measured on the widest part of the bolt head and should fit in the wheel’s lug hole.

Thread pitch: The bolt’s thread pitch is a measurement of the spacing of the threads. The thread pitch refers to the distance between each thread, measured in millimeters on metric bolts. On imperial (non-metric bolts), the pitch refers to the number of threads per inch. The easiest and most accurate way of measuring thread pitch is with a thread pitch gauge.

Seat type: The seating portion of the bolt is where it presses against the rim. On wheel bolts, there are three main seating types to choose from, and the one you use must match the rim’s design. Using the wrong type could cause the bolt to come loose or damage the wheel.

- Acorn seat (tapered, conical).

- Ball seat (rounded or spherical).

- Flat seat (flange).

Grade. A measurement of the bolt’s resistance against tearing. Use a similar grade or higher than the original bolt.

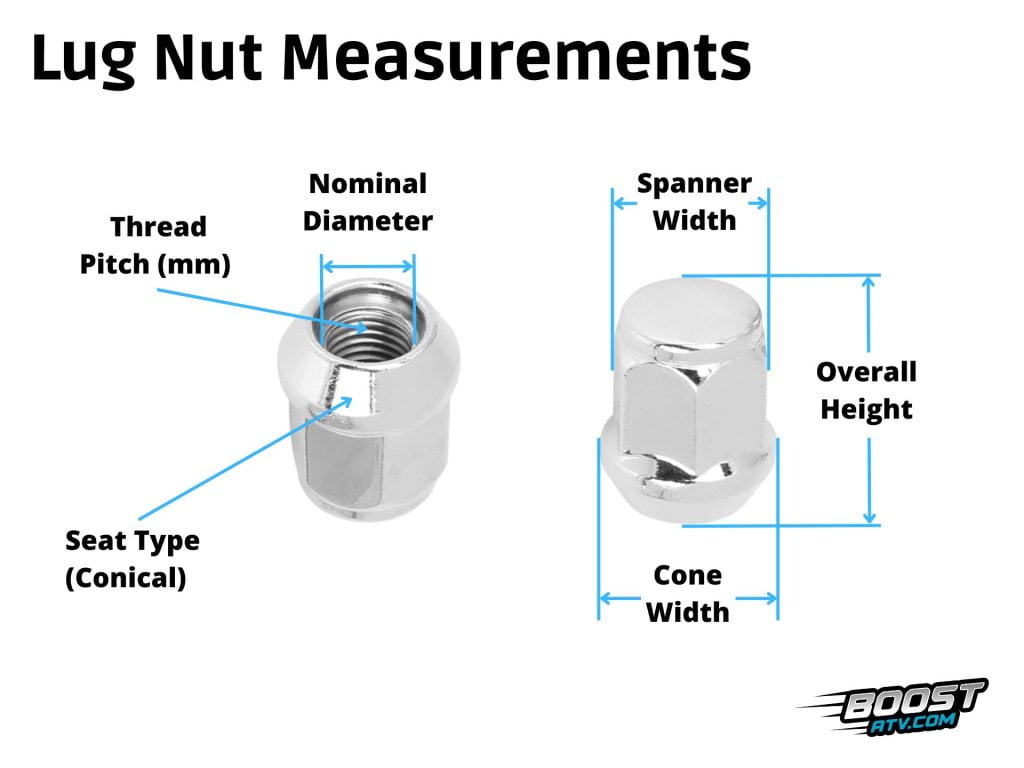

ATV Lug Nut Sizes Explained

Nominal Diameter: The nominal diameter is the inside diameter of the threaded part of the nut. Common sizes in ATVs are M10 and M12, where the number indicates the bolt diameter in millimeters.

Thread Pitch: The lug nuts thread pitch is a measurement of the spacing of the threads, which needs to match that of the wheel stud. The thread pitch refers to the distance between each thread, measured in millimeters on metric bolts. On imperial (non-metric bolts), the pitch refers to the number of threads per inch. The easiest and most accurate way of measuring thread pitch is with a thread pitch gauge. Typical sizes in ATV lug nuts are 1.25 and 1.5mm.

Overall Height: The overall length or height is measured from one end of the nut to the other.

Thread Depth: The depth of the threaded part is usually a couple of millimeters less than the overall height. Unless it’s an open-end lug nut, you need to ensure the threaded part of the nut is deep enough so the wheel stud doesn’t bottom out.

Cone Width: The cone width is measured on the widest part of the nut and needs to fit in the recessed part surrounding the wheel’s lug hole.

Spanner Width: The size socket that fits onto the lug nut hex head. Typical sizes in AATV lug nuts are 17mm and 19mm.

Lug Nut Type: Lug nuts are either open-ended or closed. You could go from an open-end bolt to a closed one if you ensure the closed nut is deep enough and all the other parameters match.

Seat Type: With lug nuts, there are several different seat types. The seat type needs to match that of the wheel’s lug hole. Using the wrong type could cause the bolt to come loose or damage the wheel. These are the most common types.

- Acorn Seat (tapered, conical): The cone seating typically has a 60-degree angle. S

- Ball Seat (rounded or spherical): This style has a more rounded form than a cone-shaped seat.

- Mag Seat (flat washer): Also known as shank style. The design features a flat washer and a cylindrical shank extending into a corresponding wheel slot for more thread engagement.

- Mag Seat (tapered): Similar to the flat mag seat with a shank but with a tapered seat rather than a flat washer.

Shank Dimensions: On lug nuts with a shank design (mag-style), you also need to consider measurements such as shank diameter and depth.

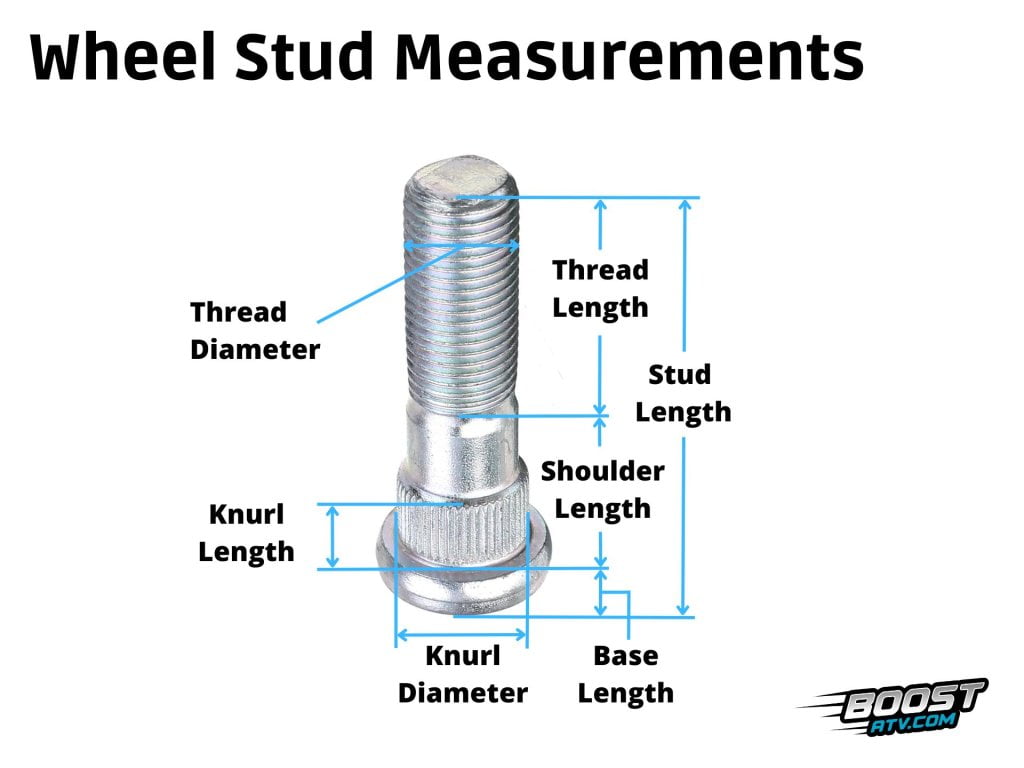

ATV Wheel Stud Sizes Explained

Thread Diameter: The thread diameter or thread size is the stud diameter measured on the threaded part.

Stud Length: The stud length is measured from the base of the slightly wider flange portion of the stud and to the end of the threaded part.

Shoulder Length: The shoulder begins where the thread ends and continues up against the base of the flange.

Knurl Length: The knurl is the splined part of the stud, and the knurl length is the length of the splined portion, not including the smooth, non-splined area between the threads and the knurl and between the knurl and the flange.

Base Length: The flange thickness.

Knurl Diameter: The stud’s diameter, measured on the splined portion.

Thread Length: The thread length is measured from where the threads begin to the threaded part’s very end.

Grade: A measurement of the stud’s resistance against tearing. Use a similar grade or higher than the original stud.

Choosing the Right Seat Type Is Important

Most ATV lug nuts and wheel bolts have a ball-shaped, conical, or flat washer-style seat type.

Your wheels are designed for a specific seat type. If you use the wrong bolt or nut, you will likely damage the wheel, and the fastener will be prone to coming loose while you are riding.

You should never use a conical wheel nut on a wheel designed for ball-shaped lug holes. Similarly, avoid using a ball-shaped lug nut on a wheel with conical lug holes.

Wheel Stud + Lug Nut or Wheel Bolt – Which Are Better?

You may wonder why some vehicles use wheel bolts while others use wheel studs and a lug nut. Here are a few reasons why.

Changing Wheels Is Easier With Studs

With studs protruding from the wheel hub, you can temporarily hang your wheel without holding it while installing it to the hub.

Wheel Studs Are Easier and Cheaper to Replace When Damaged

If you strip the threads or twist off a wheel bolt, you must replace the entire wheel hub assembly. You only need to replace the damaged stud if you strip the threads on a wheel stud.

Lug Nuts Provide a More Consistent Torque Application

Without going into the technical details, tightening a nut achieves a more consistent and accurate torque than tightening a bolt. And at the same applied torque, a nut will yield a higher clamping force than a bolt.

Installing Wheel Studs Requires a Special Tool

Replacing a broken wheel stud is much easier if you have a simple wheel stud tool to help remove the old stud and seat the new one in the wheel hub.

Wheel Bolt Designs Are Cheaper and Simpler to Manufacture

Wheel bolt designs consist of only two parts/manufacturing processes (a bolt and a tapped hole) and are cheaper to manufacture than a stud and lug nut design, which has three (a non-tapped hole, stud, and lug nut).

This may not sound like a huge difference, but it soon adds up when you multiply by four or five for each wheel, by four once more for all of the wheels, and finally with the number of vehicles produced each year.

While this approach may save on manufacturing costs upfront, it increases the cost of ownership and repairs.

When to Replace Wheel Bolts, Lug Nuts, or Studs

Here are two typical scenarios where you might need to purchase new wheel fastening hardware.

When Buying Aftermarket Wheels

Aftermarket wheels may not have the same seating type or pilot hole size as your original wheels. It is advised to buy mounting hardware as the aftermarket wheel manufacturer recommends.

When Changing From Steel Rim to Aluminum Alloy

Alloy wheels usually have a thicker center disc that requires longer wheel bolts or studs and often requires a different seating design.

Some are designed with a flat recess that requires a different lug nut but allows you to use the original length wheel studs.

What Torque to Use on ATV Lug Nuts

ATV steel rims are typically torqued at 30 – 40 ft. lbs. (41 – 54 Nm), and ATV cast aluminum rims are typically torqued at about 50 – 60 ft. lbs. (68 – 81 Nm).

Always refer to your vehicle’s owner’s manual for the recommended torque specification.

The torque to use depends on the grade of the wheel studs on your machine and can vary between make and model.

If you use anti-seize on the threads, you should reduce the torque by about 20%, as lubricated bolts turn more easily.

Your ATV’s user manual may say you should use a torque of up to 100Nm or more. But judging by my personal experience and various user experiences from ATV forums, tightening this much may result in stripped threads and broken studs.