When purchasing new ATV wheels, it is crucial that the wheels you get have the same bolt pattern as the wheel hub, or they will not fit.

In this guide, we’ve gathered everything you need to know about ATV wheel bolt and lug nut patterns, what they are, how to measure them, and some examples of the most common ATV bolt patterns.

If you want to learn the difference between wheel bolts, lug nuts, and wheel studs and what size and shape you need, you should head to this post.

What Is the Bolt Pattern and Lug Pattern on Your ATV?

Most ATVs have wheel hubs with fixed wheel studs on which the wheel attaches through the bolt holes and is secured with lug nuts.

Another configuration that is more common in automobiles is where the wheel hub has threaded holes and uses wheel bolts that go through the wheel bolt holes.

Wheel bolt pattern and lug pattern essentially refer to the same thing: the configuration of the bolt holes or wheel studs.

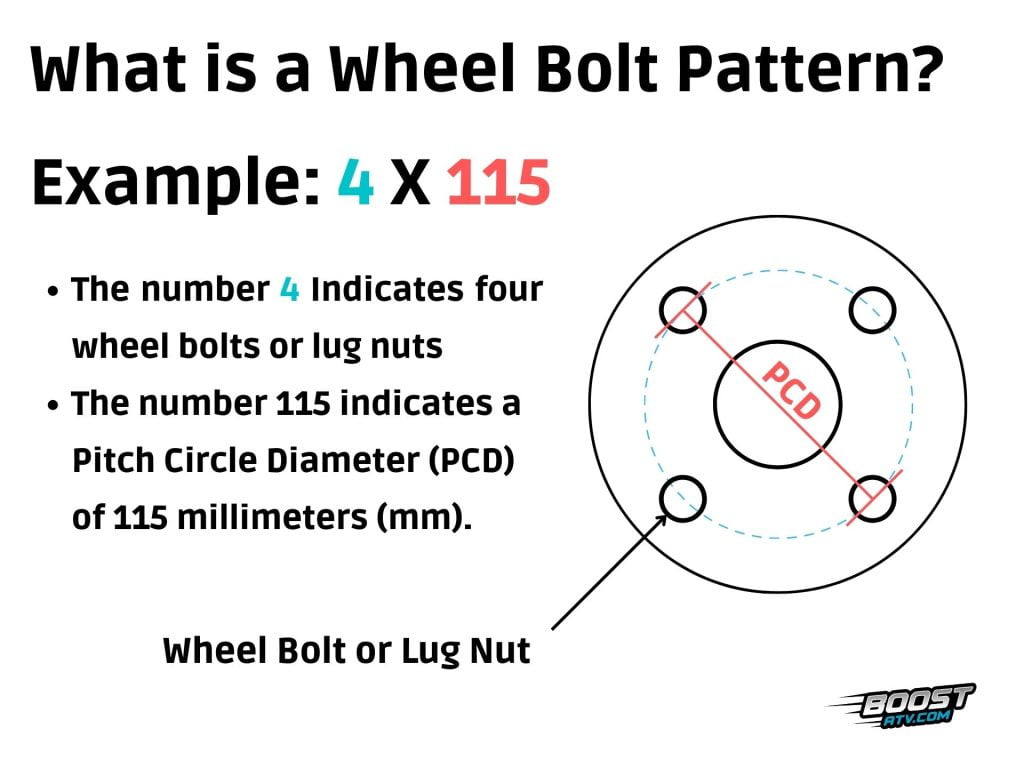

A wheel’s bolt pattern is a metric that determines the number and position of the bolt holes that must line up with the wheel studs or holes in the wheel hub. The bolt holes are evenly spaced at a diameter known as bolt circle or Pitch Circle Diameter (PCD).

A bolt circle or PCD is the diameter of an imaginary circle formed by the center of all the wheel bolts.

4×110 is a typical ATV bolt pattern where 4 indicates four-wheel bolts or lug nuts, with a PCD of 110mm.

Wheel bolt patterns come in many designs and sizes. The number of wheel bolts or lug nuts and the diameter between them varies depending on vehicle type and usage.

How to Measure the Bolt Pattern on an ATV

To know your ATV’s wheel bolt pattern, look it up in the user manual or learn how to check.

Because many wheel bolt patterns are relatively close in size, trying to determine by eye is not advised.

You’ll need a suitable measuring tool with a minimum accuracy of 1mm to get a good reading. A ruler or tape measure will work, while calipers are preferred.

Count the Number of Wheel Bolts or Lug Nuts

This step is pretty self-explanatory. On ATVs, there are typically three, four, or five nuts.

Remove One of the Wheels

It is best to measure directly on the bolt holes or studs for an accurate measurement, depending on whether the ATV uses wheel bolts or lug nuts. Alternatively, you can measure between the holes on the backside of the rim; the result should be the same.

- Place the ATV on a solid, level surface.

- Using a socket of the proper size and a ratchet, loosen all bolts or lug nuts, but do not remove them altogether.

- Place a jack on a solid part of the frame. Jack up the ATV until the wheel is off the ground.

- Use jack stands underneath the frame so the ATV doesn’t fall over you if the jack fails.

- Continue removing the bolts or lug nuts and remove the wheel from the hub.

Measure the Pitch Circle Diameter (PCD)

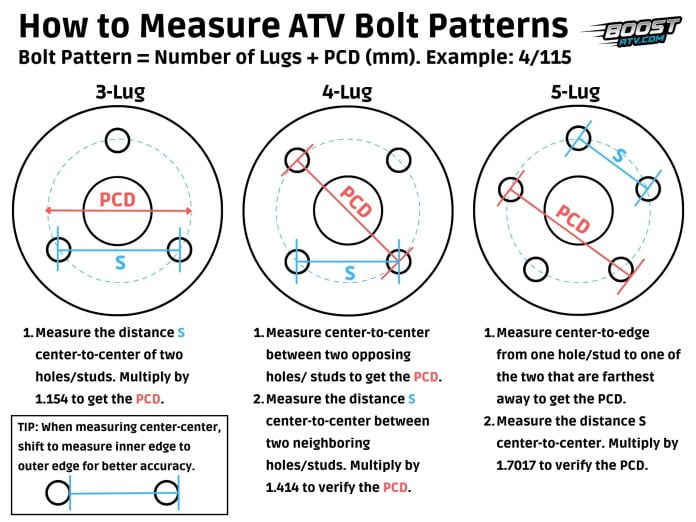

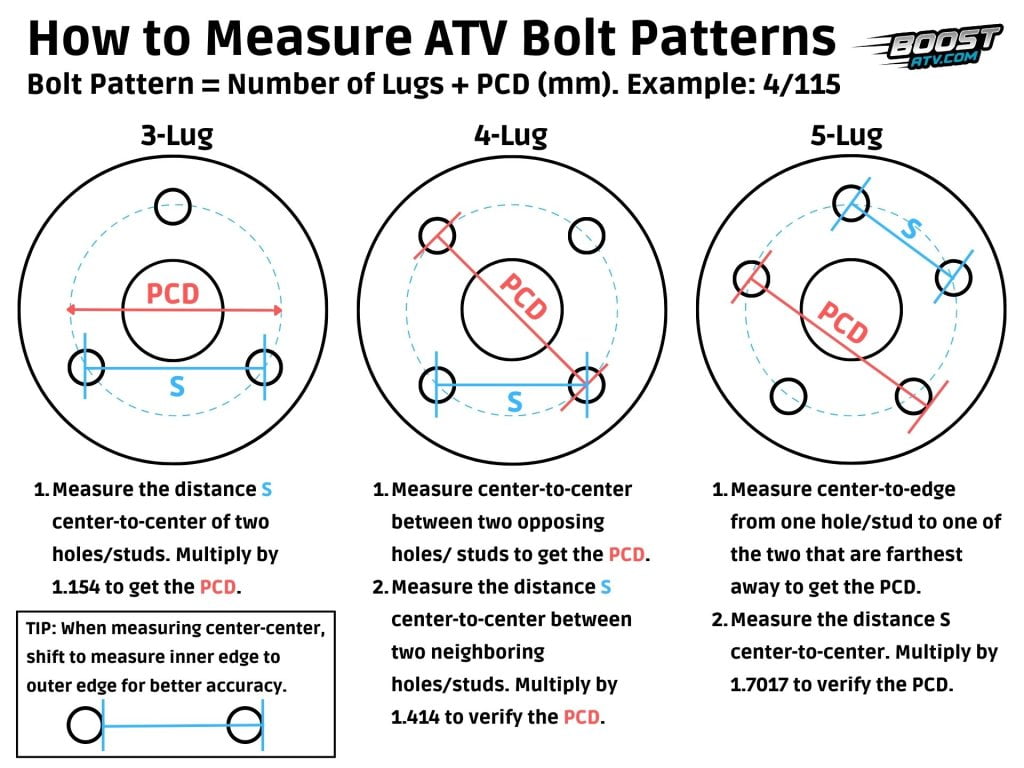

There are two ways to measure the wheel pattern. Using both methods to rule out errors in any of the readings is generally advised.

- Direct measure. This procedure involves measuring according to a predefined pattern, and the measurement equals the PCD. The measurement pattern is different depending on the number of lugs. Even-number wheels are the easiest to measure as the PCD equals the center-center distance between any two opposing lugs. Odd-number wheels require a slightly more complex procedure.

- Calculate PCD by ratios. The second method involves measuring the center-center distance between any two bolts next to each other, “S.” The distance is then multiplied according to a predefined ratio to find the PCD.

- 3-lug: S x 1.154

- 4-lug: S x 1.414

- 5-lug: S x 1.7017

Use the guidelines in the diagram below depending on how many lug nuts or wheel bolts you counted.

TIP: Measuring the center-center distance between two bolts or holes by measuring the middle does not always yield the best accuracy, as it can be hard to know exactly where the center is.

A better method is measuring from the inside of one bolt or hole and to the outside of the other. By shifting the measurement to the edges of a bolt, you have fixed points to measure against, and the measured distance equals the center-center distance.

- Three-lug pattern: There is no accurate way to measure the diameter directly on a thee lug wheel. Measure the center-center distance between two lugs and multiply by 1.154 to get the PCD.

- Four-lug pattern: Measure the center-center distance between two opposing lugs or holes to read the PCD. Then, measure the center-center distance between two neighboring lugs or holes and multiply by 1.414 to verify the PCD.

- Five-lug pattern: Measure from the back of one hole to the center of one of the two farthest holes to read the PCD. Then, measure the center-center distance between two neighboring lugs or holes and multiply by 1.7017 to verify the PCD.

Check if the Front and Rear Pattern Is the Same

On most modern 4×4 ATVs, the front and rear wheels have the same bolt pattern.

But on some models, primarily in 2×4 quad bikes and some youth ATVs, you will find that the ground wheels have a different bolt pattern than the rear.

Put the wheels you’ve just measured back on the ATV and repeat steps one through three for a different tire. If the first tire you measured was a front tire, now measure one of the rear and vice versa.

Test Fit the New Rim Before Installing a Tire

Before installing tires on your new rims or wheels, it’s advisable to test-fit them on the wheel hub to ensure they fit correctly.

Most wheel manufacturers and resellers do not accept returns for wheels that have had tires mounted on them.

The bolt pattern is not the only measurement you need when buying new rims. You also need to know the wheel offset and the wheel size.

What Are the Most Common ATV Bolt Patterns?

Modern ATVs’ most prevalent bolt patterns include 4×110, 4×115, 4×137, and 4×156.

Typically, ATV wheel measurements are in millimeters. However, some older models were measured in inches, with 4×4 being the most common size.

Three-lug wheels are uncommon in ATVs and are typically only found on some small-engined youth models designed for lower-speed, low-torque riding applications.

Four-lug wheels are what most ATV manufacturers use while using different diameters between the bolts depending on the brand, ATV size, weight, engine power, and intended use.

Five-lug wheels are no longer standard in ATVs, but some older models, like some Suzukis, used them.

ATV Bolt Pattern by Brand

Most brands use several bolt patterns but have one or two they use the most. The list below is only an overview and may be subject to change or errors. You did not buy wheels based on it.

Polaris ATV Bolt Patterns

All modern full-sized Polaris ATVs and UTVs use a 4/156 bolt pattern.

Older models typically used 4/100 or 4/4.

Honda ATV Bolt Patterns

All modern full-sized Honda ATVs except the sports models and their smaller UTVs use a 4/100 bolt pattern. Their bigger UTVs use 4/137.

Older models typically used 3/100, 4/85, 4/130, and 4/150.

Can-Am ATV Bolt Patterns

All modern full-sized Can-Am ATVs and UTVs use a 4/137 bolt pattern.

Older models typically used 4/110 or 4/144.

Arctic-Cat ATV Bolt Patterns

All modern full-sized Arctic-Cat ATVs use a 4/115 bolt pattern.

Yamaha ATV Bolt Patterns

All modern Yamaha ATVs except the sports models and most of their UTVs use a 4/110 bolt pattern. YFZ 450 racing quad and the 2019 YXZ (UTV) uses a 4/156 bolt pattern.

Suzuki ATV Bolt Patterns

All modern full-sized Suzuki ATVs use a 4/110 bolt pattern.

Older models typically used 3/90, 3/100, 3/120, 4/90, 4/112, 4/130, 4/140, 4/166 or 5/160.

Kawasaki ATV Bolt Patterns

Kawasaki ATVs with a solid rear axle use a 4/137 bolt pattern, while models with independent rear suspension use a 4/100 bolt pattern.

Their UTV models use a 4/137 or 4/156 bolt pattern.

Hisun ATV Bolt Patterns

Most Hisun ATVs use a 4X110 bolt pattern.

Why Don’t All ATVs Use the Same Bolt or Lug Pattern?

Wouldn’t it be convenient if the manufacturers came together and agreed on one universal wheel bolt pattern? Sadly, that is likely not going to happen any time soon, and there are several possible reasons why.

Different Stress-Tolerance-Requirements

A wheel with more bolts and a larger PCD can generally withstand higher forces and distribute these forces more evenly on the wheel hub and axle.

In other words, a higher number of bolts gives you a more stable and robust wheel with better handling, given the materials used are the same.

But what about single-lug wheels often used in racing? These wheels are usually crafted from stronger and much more expensive materials, which are not cost-effective or appropriate for typical ATV riding applications.

Cost

While it may not seem like a big difference, cost probably plays a role when manufacturers decide on wheel patterns.

A five-lug wheel has one more bolt to make, one more hole to drill, and a larger-diameter hub that requires more material to produce.

Weight Savings

Not only are larger diameter hubs with more bolts more expensive to manufacture, but they also add to the vehicle’s overall weight.

Non-Interchangeable Wheels Between Brands

You may have noticed the various ATV brands, for the most part, use different ATV wheel patterns. While this is pure speculation on my part, it is safe to assume part of the reason is because they want to prevent interchanging wheels between brands.

Can-Am would likely not want people using Polaris brand wheels on their ATVs and vice versa. The same assumption applies to most major ATV brands. The easiest way to avoid this is by using different wheel patterns between the brands.

Lack of Standardization

No standard dictates what wheel bolt pattern ATV manufacturers can or should use.

Wheel bolt patterns for various ATV brands and models have developed gradually over many years. Not all differences are planned or intentional; it’s just how they turned out.

When a manufacturer has already established one or two bolt patterns for their brand, swapping out or rebuilding all the production machinery for a universal pattern would be expensive.

Dual Bolt Patterns (Dual Drill)

An increasing number of wheel manufacturers offer dual bolt pattern wheels. These are wheels designed with two different bolt patterns so that one single wheel will fit a broader selection of ATV brands and models.

For instance, a dual pattern wheel might feature a 4×110/4×115 bolt pattern. This means four holes form a 4×110 bolt pattern, and if you rotate the wheel by 45 degrees, you’ll find four additional holes that create a 4×115 pattern.