This guide will tell you how to replace/install an ATV winch cable or synthetic winch rope step-by-step.

The basic procedure for replacing an ATV winch line is about the same whether you are:

- Replacing an old steel winch cable with a new one.

- Replacing a steel cable with a synthetic rope.

- Replacing a worn synthetic rope with a new one.

- Replacing a synthetic rope with a steel cable.

- Installing a synthetic winch rope or steel cable on a brand-new winch.

The main difference is how you attach the cable or rope to the winch drum (step 7) and what fairlead you should use.

Time consumption: 10-20 minutes from start to finish.

Mechanic skill level required: Low. If you know how to change a tire, you will be able to do this job.

Step 1: Get the tools and supplies you need

Before you begin disassembly, ensure you have the proper tools and supplies.

If you have not yet decided whether to install a new winch cable or a synthetic winch rope, I recommend you look at this post, where we compare steel cables vs. synthetic ropes for ATV winching.

Make sure you get the correct rope or cable for your winch

- The rated breaking strength should be at least double the rated towing capacity of the winch.

- Most cables and ropes do not come with a hook. If the one you have is damaged or of bad quality, now is the time to get a new one.

Some synthetic winch ropes come with an unfinished end where you have to splice the end loop yourself. However, most winch ropes on the market today come with an end loop straight out of the box. A metal thimble insert makes the loop extra wear-resistant.

I recommend that you get a rope that comes with an end loop. It will save you time and reduce the risk of splicing the rope incorrectly. Therefore, this guide will not cover how to make an eye splice.

Make sure you have the proper fairlead

The type of fairlead you should use depend on whether you choose a steel rope or a synthetic cable.

With a synthetic winch rope, you may use either steel roller fairleads or an aluminum hawse. A cast-iron hawse does not have a smooth enough surface and will prematurely wear the rope. An aluminum hawse, however, is much smoother, which makes it ideal for synthetic ropes.

Steel roller fairleads work fine as long as the rollers are not damaged or too corroded. The rollers must overlap in the corners where they meet, or you may get binding issues that will damage the rope. Most newer steel roller fairleads have overlapping rollers, while non-overlapping rollers are more common on older models.

Tools required

- Socket wrench set with the correct sockets and bits.

- Some winch types: Allen wrench/hex key.

- Pliers, preferably needle-nose pliers or similar.

Heavy-duty gloves.

Now that you have all the gear and tools you need, you are ready to begin replacing the cable.

Step 2: Disconnect the winch hook

Remove the locking pin (usually a split pin) and the bolt that connects the hook with the eye loop. This allows you to remove the fairlead. You will reuse the hook with the new rope or cable if it is in good shape.

Step 3: Remove the fairlead

Whether your existing fairlead needs replacing or not, you will likely have to remove it to access the winch drum. It is held in place with two bolts, one on each side. Loosen the bolts and put the fairlead to the side for now.

Step 4: Disengage the winch motor

On the side of your winch, you will find a switch that disconnects the winch motor from the cable drum. This is the free spool position, which enables you to unspool the winch cable by hand.

The design of this switch varies from manufacturer to manufacturer. On ATVs, a rotary-style knob at the very end of the winch is the most common.

On Warn winches, you should turn the knob clockwise until you hear a click or until you can’t turn it any further without applying force. If you twist the knob too far, you need to disassemble the knob to get it working again.

The drum should spin freely with the knob in the free spool position. However, the grease inside the winch gears may create some drag in cold weather. You should still be able to turn the drum by hand, but it will require more pulling force.

Step 5: Remove the old winch line from the spool

Use gloves for this step, especially if removing an old steel cable. The small metal burrs of a frayed cable will not be gentle with bare hands.

Grab the old line and pull on it so that it unspools. Pulling it by hand is better than using the winch motor to unspool the line. Unspooling with the motor may only worsen it if it’s bound up somehow. So if you are able, unspooling by hand will work the best.

Related: 6 Ways to Untangle a Stuck or Jammed-up Winch Cable

The termination point of the cable is usually mounted to the drum. There

Steel cable attachment style 1: Hole and an Allen set-screw

The cable goes through a hole in the core of the winch drum. An Allen set screw retains the cable in the hole. Loosen and altogether remove the set screw to release the cable. Take note of with hole the cable is threaded into the spool through. You must thread your new rope or cable the same way.

Steel cable attachment style 2: Hole and a wedge-shaped slot

The cable goes through a hole in the winch drum core. At one end of the hole is a wedge-shaped slot that fits a cable loop and a metal locking bead. The bead helps tighten the loop when you pull on the cable.

To remove it, push the cable from the opposite side of the loop. This will release the bead so the cable can be pulled out of the drum.

Steel cable attachment style 3: Screw to the sidewall of the winch drum

Older ATV winches often attach the cable using a screw to the sidewall of the winch drum. This method is not that common nowadays, but you may run into it if you replace an older ATV cable.

Synthetic winch rope attachment method: Through the hole and make a knot

If you’re replacing a worn synthetic rope, any methods above may have been used to hold the rope in place.

In addition, I will recommend the method where you feed the rope through the hole in the winch drum core and make a knot around itself.

It’s a good idea to take a photo of the knot before untying it. The hardest part of installing a new rope is to make a proper knot.

In step 7, I will show you how to create a knot like this.

Step 6: Inspect the winch drum and fairlead

Steel cables have been known to damage the winch drum or the fairlead rollers. Now is an excellent time to inspect them both.

Any sharp edges must be addressed before you install your new rope, or your rope will get damaged. Use a file or a piece of sandpaper to file down any burrs or grooves to a smooth surface.

Step 7 Mount the new rope or cable to the winch drum

This step depends on your winch drum style and whether you are installing a steel cable or synthetic rope.

Mounting a steel cable to the winch drum

If your winch drum has a hole and an Allen set screw, thread the end of the cable into the hole in the same direction as your old cable was sitting. Lock it in place by tightening the Allen screw snugly.

The procedure is not that different if the drum has the loop-and-metal-bead style locking mechanism.

Feed the cable through the drum hole in the same direction as the old cable. Let a few inches of cable go through the spool. It should be enough to create a loop. Bend the cable into a U-shape, and let it slide back into the slot on the winch drum.

Insert the metal bead inside the loop before you tighten the cable by pulling on the long end. Tighten as hard as you can so the cable sits firmly.

Mounting a synthetic rope to the winch drum

With synthetic ropes, it’s not that you can’t use the set screw or metal wedge method to mount the rope, but there are better ways that will make an even more slip-proof installation.

The method I find works best, and what many manufacturers recommend, is making a knot that tightens as you put tension on the rope. Here is how to do it:

1. Position the winch drum correctly

The winch drum mounting hole is a bit off-center. You need to ensure the drum is positioned correctly so the rope will begin wrapping around the thickest part of the drum when you spool it in. Which position is correct depends on which way the drum turns when you spool in.

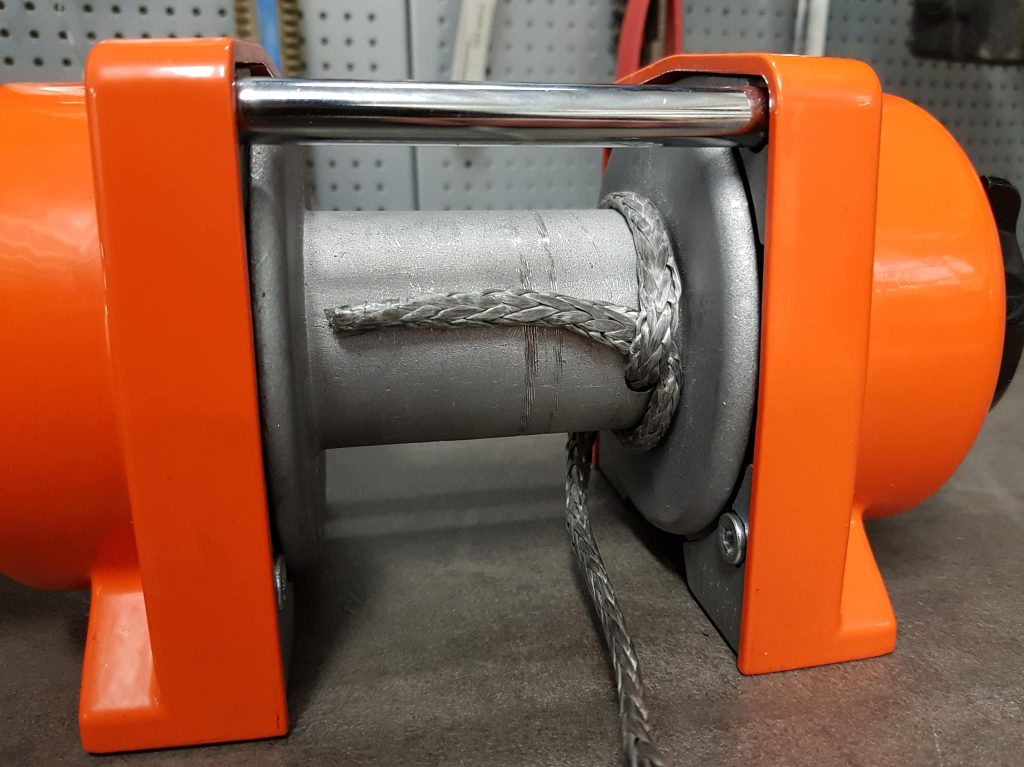

- If your winch turns backward when you spool in, the hole should be on top, as shown in the photo.

- If your winch turns forward when you spool in, rotate the drum so that the hole is closest to the bottom of the drum.

2. Feed the rope through the hole

Feed the free end of the rope through the hole, with a few inches of rope sticking out the other side of the drum.

3. Rotate the drum 180 degrees

Rotate the spool 180 degrees upwards so the short end of rope points towards you. If the hole is positioned at the bottom, see step 1 above, you need to rotate the spool 180 degrees downwards instead.

Grab both the short and long end of the rope.

While holding both ropes, rotate the spool back down 180 degrees. Again, if the hole through the drum was positioned near the bottom after finishing step 1, you will now need to rotate the drum up instead. The result should look the same regardless of which direction your winch turns. The only difference is that the knot will be upside down.

The shorter length of rope is now forming a loop around the spool. Allow a bit of slack, then thread the shorter end of the rope from the outside in, passing it under itself to create a knot.

Tuck the shorter length of rope under its own loop to create the knot.

The shorter length of rope should now lay across the spool.

Tighten the knot by holding the shorter length of rope with one hand while pulling on the longer length of rope with the other.

Slide the knot all the way outwards on the spool. You are now ready to begin reeling the rope back onto the spool.

Step 8: Engage the winch motor

Turn off the free-spool knob by rotating it opposite to what you did earlier. This will engage the winch motor so you can spool the new rope or cable onto the winch drum.

Step 9: Spool the rope or cable onto the winch drum

From now on, ensure you keep your hands safe from the winch, as you will use the winch motor to spool the new rope or cable onto the drum.

The winch line must be kept under constant tension as you spool it onto the drum. Otherwise, it may get jammed between lower layers of rope when you use the winch later.

You will also need to guide the rope so that it spools neatly. Guide the rope at a steady pace from one side to the other. You should get a flat and even layer of rope across the entire width of the drum.

If you have a remote, it is possible to do this step alone. But getting the rope to wrap neatly is easier if you get help from a friend.

One person should operate the winch controls while the other guide and keep the rope under tension.

Lay out the winch line before you start spooling. This will reduce the risk of tangling the rope.

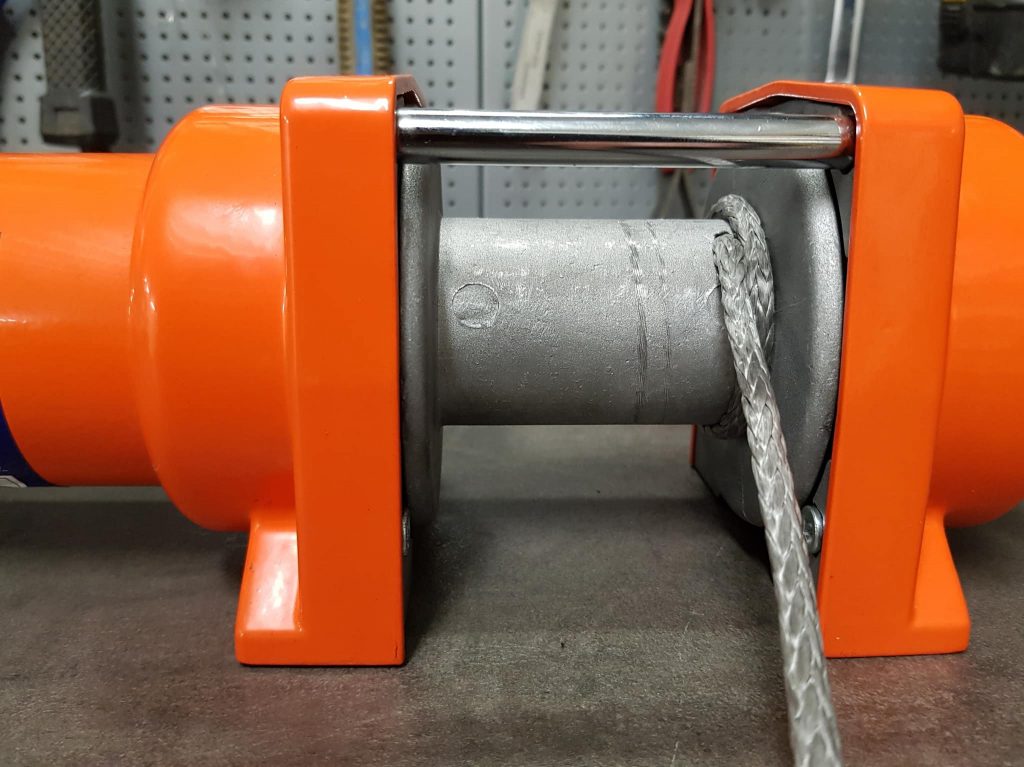

Start spooling from the knot side and work your way to the other side of the drum. Each rope winding should be touching the previous one.

This is how it should look after half a turn.

This is how it should look after one whole turn.

Then after two turns.

Continue winding until you get a flat layer of rope across the width of the winch drum.

When you reach the edge, it’s time to turn back and lay a new layer of rope across the drum. Ensure you maintain a steady pull on the winch line and continue until the rope or cable has been spooled onto the drum.

Use the same method to spool a steel cable if that is what you are installing. Make sure to use gloves.

Start at one end of the drum.

And work your way across the width of the drum in a flat, smooth pattern.

In this photo, I’m using this method for installing a synthetic winch rope on my father’s new Textron. The steel cable had to go.

Step 10: Install the fairlead and winch hook

Thread the cable through the fairlead and mount the fairlead using the proper hardware.

Ensure the winch line won’t scrape against the fairlead mounting plate. There should be at least 1/4″ clearance between the fairlead openings and the edges of the mounting plate.

If you are replacing your steel roller fairlead with an aluminum hawse, you may or may

Therefore, looking at your mounts before buying the new hawse is always a good idea to ensure it will fit. It’s much easier to choose a different model with a slightly different design than to struggle with bolts that don’t fit.

Step 11: Install a bump stop

To protect your fairlead from being damaged, installing a rubber bump stop is recommended. They are vital if you replace your steel rollers with a softer material, aluminum hawse.

If you don’t have one right now, skip this step, but add one later.

Step 12: Install the winch hook

Install the winch hook, and you are done. Bend the split pin so the bolt won’t fall out.

You are now done replacing the winch cable or rope of your ATV.

Recommended additional maintenance steps

When you perform this job, it’s recommended that you perform a couple of quick and easy maintenance steps while at it. These will help prevent some common issues you may encounter while operating your winch later.

Step 13: Check and clean the winch terminals

Corroded or loose terminals on your winch are a common cause of a winch that will not work. It’s also a common cause of a battery that keeps draining. In this post, I look at other possible reasons for a battery that keeps going dead.

Disconnect both terminals and remove any dirt or corrosion using a copper wire brush or fine sandpaper. Repair or replace any damaged wire or connectors before you reconnect the connectors to the terminals.

Step 14: Check the winch mounting bolts

It is not uncommon that a winch bolt or two may break or come loose. Now is the perfect time to ensure all bolts are in place and not damaged. Replace any missing or broken bolts with the correct spec new ones.

Related questions

Why does your ATV plow winch cable keep breaking?

If your steel winch cable keeps getting flat spots and breaking even under very little stress, replacing it with a synthetic winch rope is a good idea. Also, replace the roller fairlead with a hawse fairlead to go with the synthetic rope. This setup will last a lot longer.

What size cable do you need for your ATV?

The cable should be rated at least double the pulling capacity of your winch. Avoid getting a rope or cable that is too thick, as it will reduce how much you can fit on the spool. Typical synthetic rope size is 3/16 inch (5mm), while steel wires generally are slightly smaller with a size of 5/32 inch (4mm). Typical ATV winch cable length is 50 ft. (15m).