Most ATVs today come equipped with electronic power steering (EPS). Many ATV riders, myself included, will never go back to manual steering after experiencing the advantages of power steering.

But how does ATV power steering work? ATVs use direct-link electric power steering (EPS), where an electric motor assists the rider in turning the wheels. Sensors register the position and what torque is being applied to the steering column. A computer module then controls the direction of and how much torque the motor needs to apply.

Before we look at the specifics of ATV power steering systems, it’s a good idea to know the basic principles of how any power steering system works.

Why Do We Need Power Steering on an ATV?

The primary purpose of a power steering system is to reduce the physical effort required to turn the steered wheels.

Another great selling point for having power steering on an ATV is how it reduces handlebar whip. The motor cushion the forces that transfer from the wheels and up to the handlebars from hitting rocks and other objects. This feature is handy if you often ride in rough terrain.

All Power Steering Systems Use the Same Basic Principles

- Forces from the steering wheel or handlebar and down to the wheels are enhanced.

- Forces going from the wheels to the steering wheel or handlebar get reduced.

- The system operates completely automatically, the driver only needs to turn the steering wheel or handlebar, and the system does the rest of the job.

- The input force applied by the driver is sent through a mechanical assembly with a motor that enhances this input force to a more powerful output force. The enhanced output force then goes to turn the front wheels.

- Forces coming from the wheels hitting objects get scaled down by the same mechanical assembly before going up to the steering wheel or handlebar.

But the mechanics behind what makes the wheels turn are not all the same. There are, in fact, quite a few variations of power steering systems out there.

Electric and Hydraulic Power Steering Systems

The unit that provides the extra steering power is called an actuator, where the most common types are electric and hydraulic.

The job of the actuator is to convert and enhance the rotational motion from the steering column into a linear motion that goes out to the steered wheels.

Direct and Non-Direct Link Power Steering Systems

Some steering systems are designed with a direct mechanical link from the steering column and out to the steered wheels.

A solid steel shaft goes from the handlebar and down to the actuator, through metal gears inside the actuator, and then out to the steered wheels.

With a system like this, it is still possible to turn the wheels even if the actuator stops working or the system fails to provide steering assistance for some other reason.

However, if the system fails, it will demand a significantly greater physical effort from the rider to steer the wheels.

Similarly, if the hydraulic pump on a hydraulic system breaks, it is still possible to turn the wheels, but it’s much harder to turn the steering wheel.

The backup of having a direct mechanical link is a nice safety feature that may help prevent accidents.

Non-direct link systems have no mechanical connection between the steering column and the wheels. It uses sensors that register movement in the steering column.

An electric signal is sent via an electrical wire, through a small computer for processing, before going down to the power steering unit. These are known as drive-by-wire systems.

The sensors tell the power steering unit which direction, how fast, and how powerful it should turn the wheels. With no direct link, you cannot turn the wheels if the electronics fail.

What Type of Power Steering System Do ATVs Use?

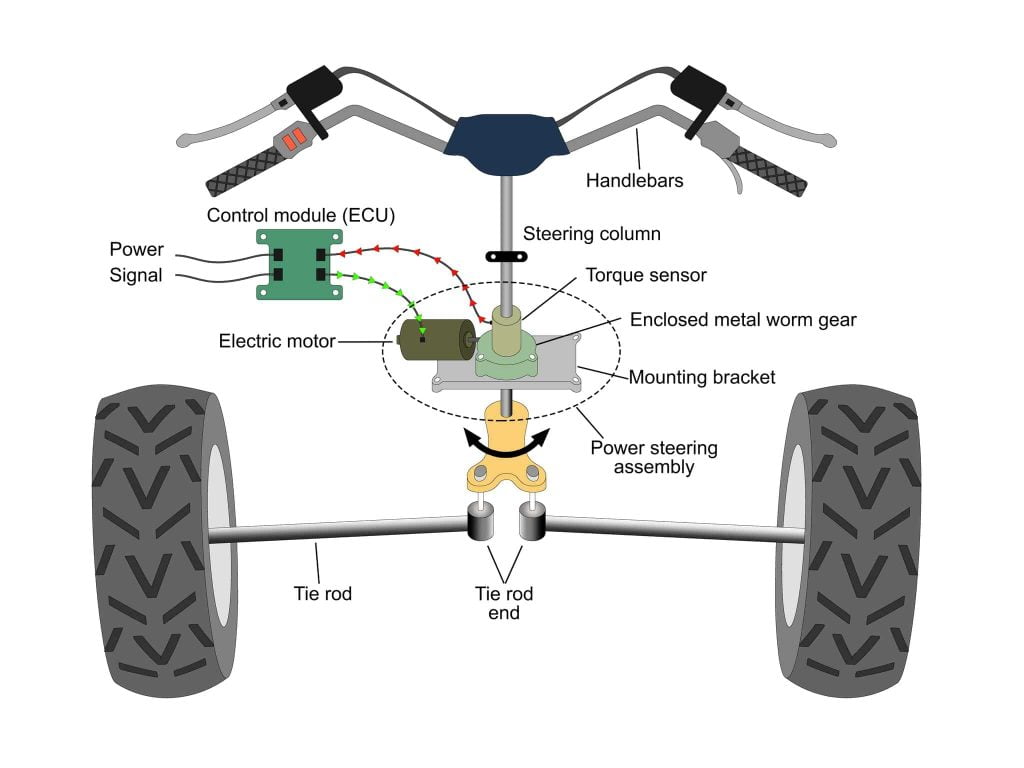

ATVs use what is referred to as a direct-link electronic power steering system. It consists of these main components:

Handlebar

The rider applies the input force to the system through the handlebar.

Steering Column

The input force gets transferred from the handlebar and down to the power steering assembly through the steering column.

Power Steering Assembly

The assembly consists of these components:

- Torque sensor: Registers the rotating connection shaft’s speed, direction, and torque. It sends an electric signal to the ECU.

- Electric motor: Small but high torque electric DC motor that helps to turn the steering column in the desired direction, torque, and speed.

- Metal worm gears: Converts the rotational motion from the steering column into a linear motion that goes to the steered wheels.

- Metal housing and mounting brackets: Make sure the other components are protected from water and impact, as well as properly

Computer Module (ECU)

The ECY or ECM is a unit that processes the signal from the torque sensor before sending it back down to control the electric motor. The signal from the ECU tells the electric motor what direction, how fast, and with what torque it should turn.

Related: Demystifying the ATV ECU/ECM: What You Need to Know

Tie Rods and Tie Rod Ends

Tie rods and tie rod ends serve as connectors between the power steering system and wheel hubs. They transfer the steering motion directly to the wheel hubs, enabling the wheels to turn.

ATV Brands Vary in Power Steering Systems

All ATV power steering systems use the basic components listed above. In principle, they all work the same way.

But, there are some variations between the brands in actual user experience. The most noticeable difference is how they control and adjust how much power the system provides.

Different riding situations require different amounts of force to turn the wheels.

When riding at high speeds on smooth surfaces, the assistance needed from the electric motor to steer the wheels is minimal.

Conversely, during technical rides on rough terrains or through deep mud, a significantly higher amount of torque is required to alter the wheels’ direction.

The same applies when changing to different wheel sizes; it requires more torque to turn larger wheels. This is what you should know before installing bigger tires on your ATV.

So the power system should be able to adapt for a better user experience in various riding situations.

Polaris, for instance, offers a system that uses sensors to tell how much force the system has to provide at any given moment. A so-called variable-assist power steering system.

The system then automatically adjusts the torque from the power steering unit. This works flawlessly for the most part, and the rider doesn’t even notice the system’s adjustments.

Can-Am uses a slightly different approach. Their tri-mode dynamic power steering (DPS) system offers three power output levels for the driver to choose from. With the push of a button, you can choose between low, medium, and high steering output power.

I prefer the Polaris type because it adapts automatically. Others prefer the ability to adjust themselves. In the end, it all boils down to personal preference.

Why ATVs Use a Direct Link Electric Power Steering System

There are pros and cons to all different variations of power steering systems available. These factors determine which system is better suited for various vehicles.

When choosing and designing power steering systems for an ATV, there are a few critical factors the designers must aim for:

- The engineers must choose and design components that help keep the ATV’s overall weight down.

- The system must be simple, robust, and durable to handle rough use.

- It requires a high power output (torque) to turn big wheels or tracks at low speeds.

- It has to be cost-efficient.

Reasons ATVs use direct link electric power steering and not hydraulic:

- Hydraulic servo systems are large and heavy compared to electrical systems. A belt-driven hydraulic oil pump, oil, and hoses add significant weight.

- Electric systems, with their few and small components, constitute a relatively lightweight system.

- Electric systems are physically small and simple in their design. This makes it easier to fit on a compact vehicle like an ATV.

- Hydraulic systems are generally more powerful, but electric systems have enough power for a lightweight ATV.

- Electric systems are more fuel-efficient. The electric motor only runs when needed, but the hydraulic pump runs continuously.

- Electric systems are simpler to manufacture and maintain. No belt drive accessories are connected to the ATVs engine, and no high-pressure hydraulic hoses or steering gear is mounted to the frame.

- Electric systems are cheaper.

- With an ECU on an electrical system, the manufacturers can design the system to adapt to various driving conditions. It can automatically increase or reduce torque, steering response, and dampening for optimal riding and handling.

- With a direct link system, the rider will still be able to turn the wheels even if something breaks in the electric part of the system. It just requires using more force.

By this point, you may wonder whether spending the extra money on power steering for your ATV is worth it?

ATV Power Steering FAQ

Can You Add Power Steering to an ATV?

There are aftermarket kits available that enable you to install power steering on almost any ATV.

My Power Steering Has Stopped Working – What Is Wrong?

When an ATV power steering for no apparent reason stops working, it is often because the sensor that’s supposed to register the position of the wheels has lost track of them. When this happens, the system shuts down as a safety measure.

Stop the ATV and turn the key to the OFF position to fix the issue. When you start the engine, the sensor will regain control of the wheel position, and the system should work again.

Do Four-Wheelers Have Power Steering?

Most four-wheelers on the market today have power steering as an option. The cheapest models, however, do not have this system available.

What is ATV EPS?

When an ATV has EPS, it has electronic power steering. A small electric motor enhances the force you apply to the steering handle, making the ATV much easier to steer.

How Important Is Power Steering on ATV?

Many riders think having power steering is very important. Power steering is beneficial to prevent fatigue from longer ATV rides, as well as for riders with mobility issues. When installing tracks on an ATV, having power steering is a must.

How to Tell if an ATV Has Power Steering?

You should be able to feel how the power steering system helps to turn the wheels on an ATV that has this system installed. At the bottom of the steering column, there will be an EPS unit on ATVs with power steering.

Wrapping Up

In conclusion, power steering systems, whether hydraulic, electric, or electric-hydraulic, provide tremendous benefits to ATV riders, enhancing the vehicle’s maneuverability and reducing rider fatigue.

By understanding how each system works and the advantages they offer, you can make a more informed decision when investing in your ATV.

Adding power steering will undoubtedly elevate your off-road experience to a whole new level, regardless of your chosen type.